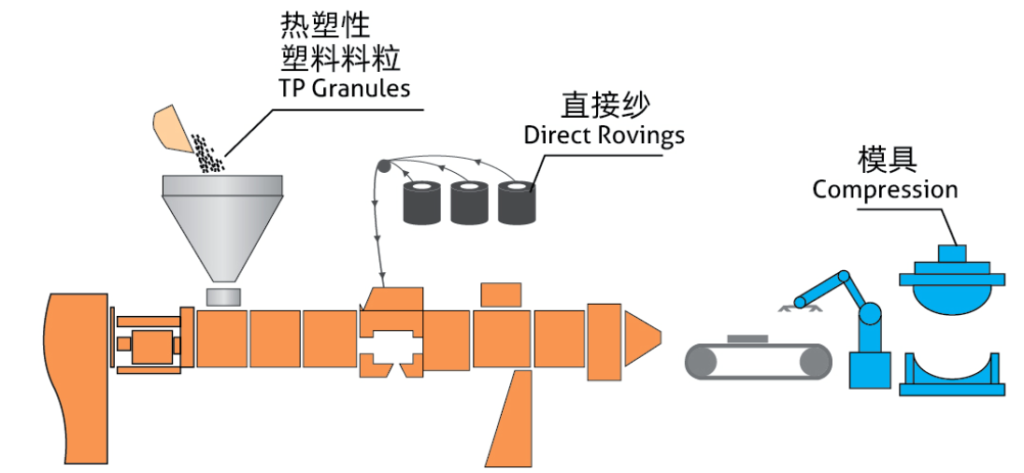

LFT-D

将聚合物和粗纱经过双螺杆挤出机混合挤出,将挤出的混合料直接注塑成型或模压成型。

Polymer pellets and glass roving are all introduced into a twin-screw extruder where the polymer is melted and compound is formed. Then the molten compound is directly molded into the final parts by injection or compression molding process.

LFT-G

玻璃纤维在牵引设备的拉引作用下通过熔融聚合物浸渍,经冷却后切割成粒料。

The thermoplastic polymer is heated to a molten phase and pumped into the die-head. The continuous roving is pulled through a dispersion die to ensure the glass fiber and polymer impregrated fully and to get consolidated rods. After cooling, the rod is chopped into reinforced pellets.

LFT用无碱玻璃纤维直接无捻粗纱

Direct Rovings for LFT

采用硅烷基偶联剂、专用浸润剂配方,与PP、PA、TPU、PET等基体树脂具有良好的相容性。

Coated with a silane-based sizing and compatible with PP, PA, TPU and PET resins.

| 产品牌号 Product Code | 纤维直径(㎛) Filament Diameter | 适用树脂 Resin Compatibility | 产品特点 Product Features |

| 352B | 17 | PA, TPU, PET | 优异的工艺性能和力学性能 Excellent processing and mechanical properties |

| 362H | 17 | PP | 适合高张力体系,力学性能高 High mechanical properties, suitable for high tension system |

| 362J | 17 | PP | 适合低张力体系,分散性好 Good dispersion, suitable for low tension system |