988A-Roving for Thermoplastics

Specification

Additional information

| Glass type | E |

|---|---|

| Sizing type | Silane |

| Typical filament diameter(µm) | 11 |

| Typical linear density(tex) | 500 |

| Example | EDR17-2400-988A |

| Resin compatibility | Multiple resin systems |

| Typical Applications | Thermoplastic pellets/granulates. Key applications include automotive parts, electrical & electronics, mechanical tools, chemical corrosion resistance and sports goods. |

| Product features | ·Good extrusion shear property and easy fiber dispersion, improving efficiency |

Introduction

Product introduction

988A Roving for Thermoplastics is an ideal reinforcement for thermoplastics. It is coated with a silane-based sizing compatible with multiple resin systems.

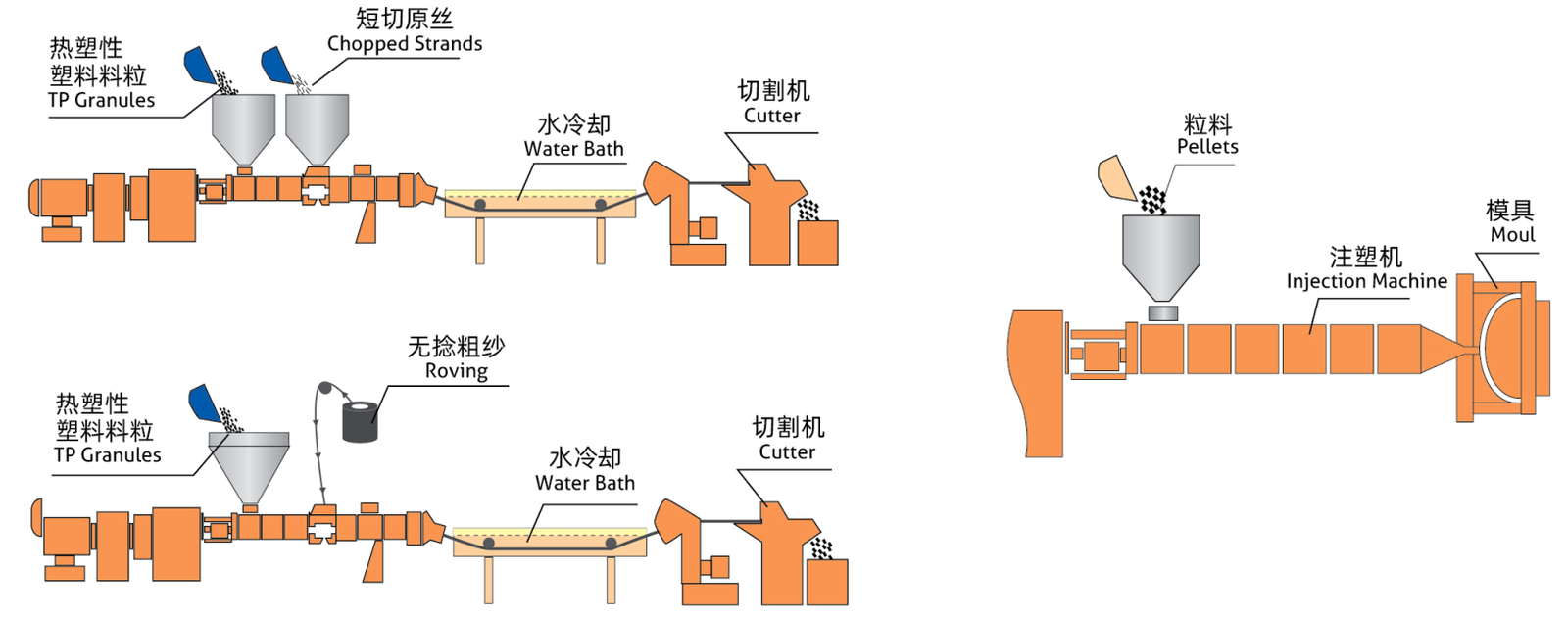

988A is typically designed for the twin screw extrusion process to manufacture thermoplastic pellets/granulates. Key applications include automotive parts, electrical & electronics, mechanical tools, chemical corrosion resistance and sports goods.

Technical Parameters